What are typical lead times? ▾

Simple customizations can ship in days. Ground-up designs with tooling typically take 4–8 weeks depending on complexity.

Do you have minimum order quantities (MOQs)? ▾

No strict MOQs. We support one-offs, pilot runs, and mass production.

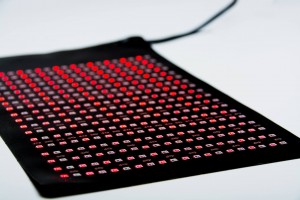

Does my project need to be related to LEDs? ▾

No. While LEDs are our specialty, we also design and produce a wide range of electronic devices, drivers, housings, and even custom molds.

What aspects of design do you handle? ▾

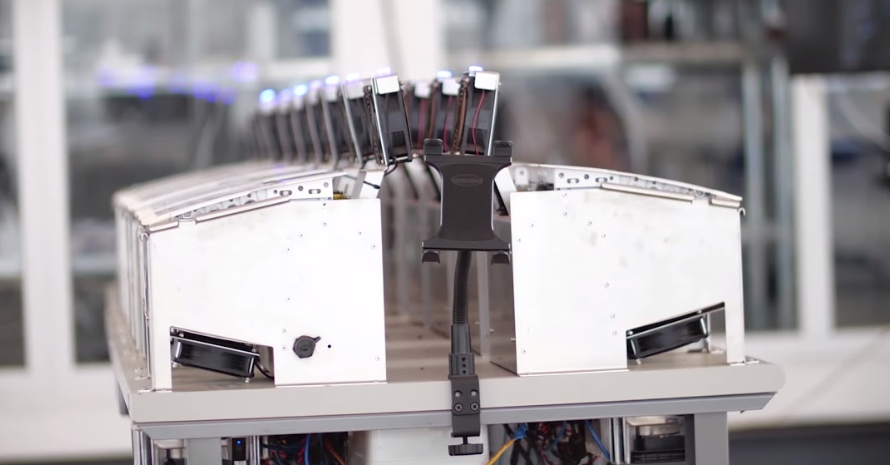

We cover mechanical design, electrical/PCB design, optics, sealing, software/firmware, injection molding, and full product engineering.

What quality controls do you have? ▾

Quality is built into our system: we use poka-yoke (mistake-proofing), automation, inventory control, and ongoing process improvement to maintain consistency.

Can you sign an NDA? ▾

Absolutely. We frequently execute mutual NDAs before diving into details.

How do I get started with my custom project? ▾

Just fill out the Project Questionnaire or email us your requirements. That gives us enough detail to start evaluating your idea.